Thanks to a team of engineers and skilled technicians TFT Dry Air Solutions follows the realization of the machinery at 360 °, from design to construction, from start-up to the after-sales service. Great experience, continuous technological research, flexibility in the design and manufacture make of TFT Dry Air Solutions a reliable and competent partner.

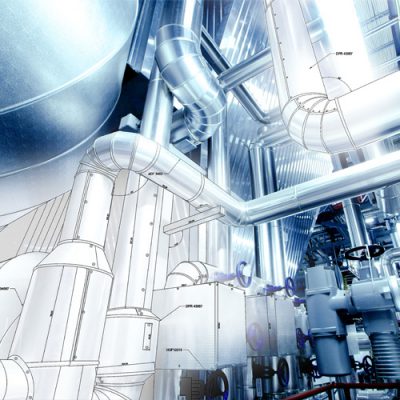

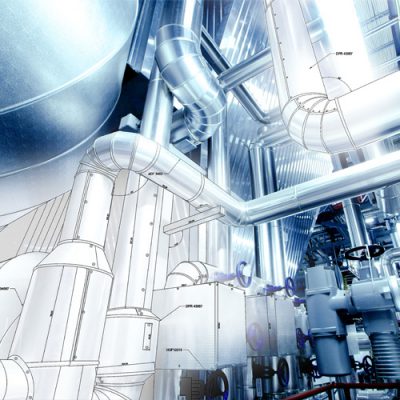

Our R&D department designs each model with CAD 2D-3D systems studying for both standard products as well as customized configurations for more efficient technology in accordance with the conditions of employment and with the needs of the customer.

The process of construction and assembly of the machines is done in our factory through different work centers CNC assisted by CAM systems. Testing and quality control activities take place according to certificates criteria respecting high quality standards and internationally recognized.

The primary testing of equipment is performed directly in our facility, with the least expenditure of resources and time for the customer. This is possible thanks to a start-up system extremely easy and to the PLC management software developed by TFT Dry Air Solutions that allows you to verify the functionality of the machinery in the factory.

Our technicians are available and prepared to perform the equipment on site, worldwide.

PLC – Programming Logic Control. TFT has developed a cutting edge proprietary software for electronic control of the functions of the machine. Installed as standard on all models, the PLC program operates independently and automatically all the phases of the drying process by simplifying not only the monitoring but also the ordinary and extraordinary maintenance.

Easy Maintenance. Our staff is able to provide direct assistance on facilities around the world, from mass in work to the repair of occasional failure, from telephone assistance to the programmed one. To reduce the costs of maintenance on the plants outside Italy (or at least more than 100 km from our place of business) TFT Dry Air Solutions has designed a program of training and upgrading of personnel in partnership with our official distributors.

Custom-made Solutions. TFT Dry Air Solutions as the name suggests, is a company specialized in the research and implementation of customized solutions for dehumidification in every industry and field of use. With a team of highly skilled engineers and a versatile production facility, we are able to customize the machinery according to the specific needs and demands of every client by the tannery that needs a good dryer to keep the product quality to the power plant that needs a good dehumidification for maintaining the turbines during maintenance.