The new online calculation software AIRDRYCALC is now available.

Send us an email with a request for access requirements and experience the convenience of calculation from all networked devices (DeskTop, Smartphone and Tablet).

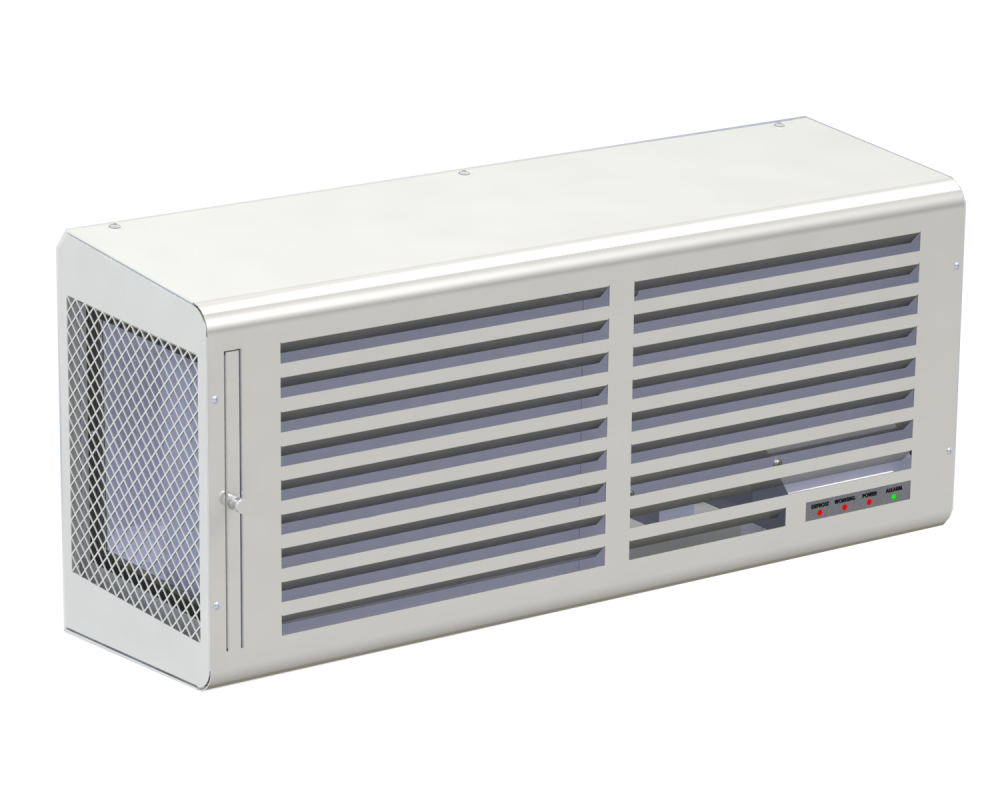

New family of adsorption dehumidifiers AD100E/AD270E/AD420E/AD550E/AD750E/AD700E/AD820E/AD1250E, ask our sales staff for information or download the brochure in the Download section.

New models of condensing dehumidifiers for industrial and swimming pool environments, for fixed or portable installation. For further information please visit the dedicated section where you can download the brochure.

| INSTALLATION | Electric pow. KW | Thermal pow. KW | Smc Methane | Cost per hour € | Cycle cost € | Drying time |

| Current | 43 | 935 | 110 | 58,10 | 697,20 | 10/12 ore |

| TFT Solution | 195 | 43 | 4,40 | 41 | 328,00 | 6/8 ore |

Lot of news will be presented during this year.

Stay tuned and follow us on LinkedIn